Crafting Colours at Pabrik Tegel Kunci

Tania Utomo (T) visits Pabrik Tegel Kunci's Mega Puspa Arifien Karang (M)

by wjournal

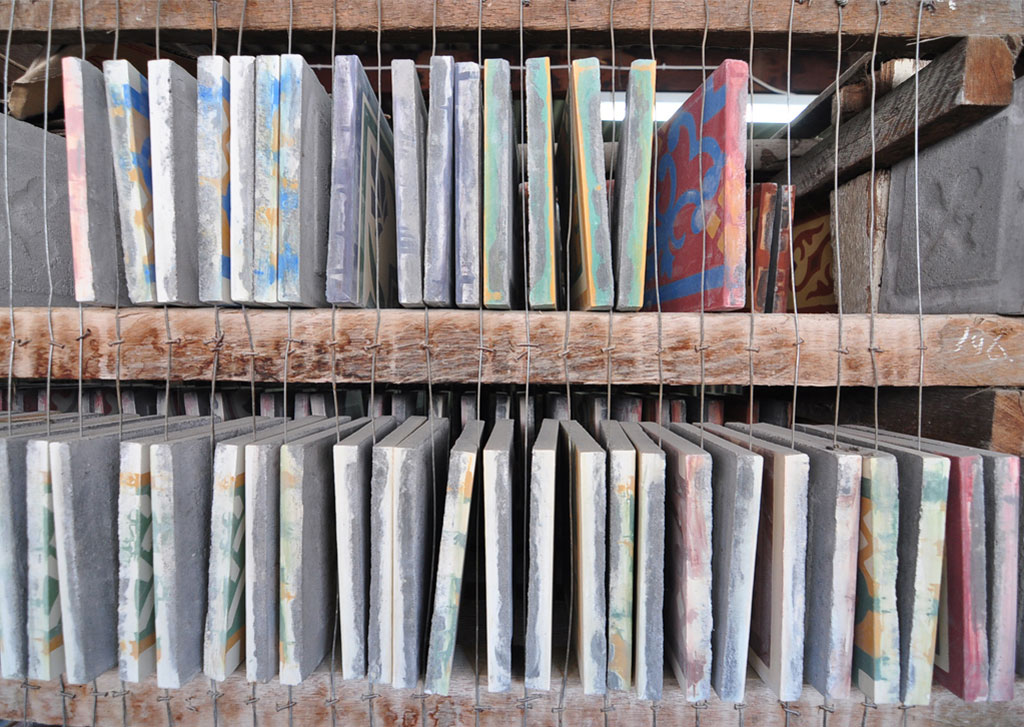

In the middle of the busy streets of Yogyakarta, right next to the crowded tourists’ district of Pathuk, an old building stands covered in washed paint and rustic windows. Inside, sounds of machines humming, water dripping, songs from the radio, and people talking and scurrying here and there fills the dusty spacious room. The vibrant scene is the daily work space of the 20 talented craftsmen of Pabrik Tegel Kunci, a factory whose works have decorated the floors and walls of homes, restaurants, and even the royal palace of Yogyakarta. Working in pairs with just a simple set of tools, they craft each of the cement tiles individually, using the same method since the factory first opened in 1929. Relying much on the skills of the workers, each tiles has to go through a handful of processes, all done by the proficient hands of the craftsmen.

The factory has gone through trials and tribulations during the first decades of its existence. After a prolonged ownership dispute with the government, the factory was left neglected for a few years, causing equipment damages that stopped production entirely. But Pabrik Tegel Kunci once again opened its doors when Mega Puspa Arifien Karang from Matta Art & Craft took over the factory in 1998, reviving Yogyakarta’s handmade tile industry and renewing public interest in locally produced goods in the process. With a background in metal craft, Mega stepped in to help restore the damages herself, enabling Pabrik Tegel Kunci to once again produce their beautiful cement tiles. Her fascination with the handmade process of tile making helped maintain the traditional methods originally used by the factory, which attracted local and international customers and gained a reputable name in the industry. Today, Pabrik Tegel Kunci continues to amaze us with the skills of their craftsmen that produce hundreds of beautiful tiles each day.

T

What is a typical day for Pabrik Tegel Kunci?

M

We divide the working schedule into two shifts to maximize our production capacity. The first shift starts at 8 and finish at 3.30 pm, with a lunch break at 12. Usually the workers would use that break for a nap, because their work requires a lot of concentration, so taking breaks is necessary, and the second shift starts at 4 and finishes at 8.

T

How did you first get into the project?

M

I happen to know Mrs. Berni Sulaiman, the wife of the original owner of the factory. She knew I had a background in metal craft and she invited me to visit the factory. It was a year later that I got the chance to visit and when I first saw the production room I was charmed by all the different colorful patterns of the tiles. Some of the machines were not working and there were only 4 workers. But seeing those tiles I thought it would be such a loss if they closed down the factory, so we decided to take over.

T

What is the most rewarding moment during your work?

M

It would be when our products are recommended by our customers. It doesn’t matter how big the project is, it could be a hotel or even a small house, but it is very gratifying to know that they are pleased with our products. And to see our tiles put in such beautiful places is such a good feeling because in the factory they all look so dusty, but when put in other surroundings they look wonderful.

T

What do you think are the limitation in doing work by hand?

M

The biggest issue would be time efficiency. Another issue is that sometimes there are customers who demand the perfect accuracy, which we are not capable of because of the handmade process. We are not capable of producing tiles with the exact same color tone, so each would be slightly different. But that is what distinguishes our products from ceramic tiles, and it is exactly why I decided to stick with this process, because I find those imperfections to be beautiful. So I see it as both a limitation and an advantage.

T

Do you intend on incorporating machines on your crafting process?

M

The only machines we use is a hydraulic pressing machine to press the tile. Currently we are developing a plan for a new factory. It would be more modern, but we still want to keep the handmade process. What we want to improve is the production line. Now the workers have to lift the tiles here and there, which is not very effective. In the new factory we want the human resources to be focused on the crafting of the tiles, and the production line to be aided by tools.

T

What would be your dream creative project?

M

I really miss getting into the crafting process because lately I’m handling more of the business side of the factory. I really wanted to design handbags. I told my niece about the idea and she was really interested, and now she is developing her own line of handbags.

T

What keeps you going?

M

During our effort to restore the factory, everyone used to be so skeptical about it. But it was the skepticism that kept me going, because I was so sure that we could get it running again. When I first visited the factory, all the floors were covered with the tiles, it was so colorful and I was instantly captivated. All that curiosity is what keeps me going.

–

Thank You

Pabrik Tegel dan Beton Cap Kunci

Mega Puspa Arifien Karang & Family

Pabrik Tegel dan Beton Cap Kunci

Jl. KS Tubun 95

Yogyakarta

T: 0274566432

tegelkunci.com